- Home

- Products

- Groundwork Materials: Piles, Pipes & More

- Steel Sheet Piles for Retaining Walls & Foundations

Steel Sheet Piles for Retaining Walls, Foundations, and Excavations

Built for Pressure: Why Modern Projects Demand Steel Sheet Piles

Whether stabilizing an excavation, supporting a foundation, or constructing a watertight barrier, steel sheet piles play a critical role in controlling ground movement and managing site constraints. Urban and coastal developments in particular require solutions that combine structural strength with efficient, low-impact installation methods — all while meeting environmental and code requirements.

Many conventional earth-retention methods demand excessive space, extended construction windows, or heavy-impact equipment that limits site access. These limitations become especially problematic in built-up areas, where vibration control, noise restrictions, and traffic management are essential. Steel sheet piles, with their modular form and press-in installation options, address these challenges with speed and precision.

For contractors and engineers operating in time-sensitive, technically constrained environments, sheet piling is more than just a structural necessity — it’s a strategic choice. From cofferdams and quay walls to deep foundation support, properly selected and installed piles can reduce risk, lower costs, and unlock valuable construction efficiency.

Our Approach to Steel Sheet Piling

At A Priori Source, we supply high-performance steel sheet piles engineered to meet the technical, logistical, and environmental challenges of today’s construction sites. Whether the goal is excavation support, flood protection, or structural reinforcement, we help contractors and engineers find the right sheet pile profiles for their site-specific conditions and regulatory requirements.

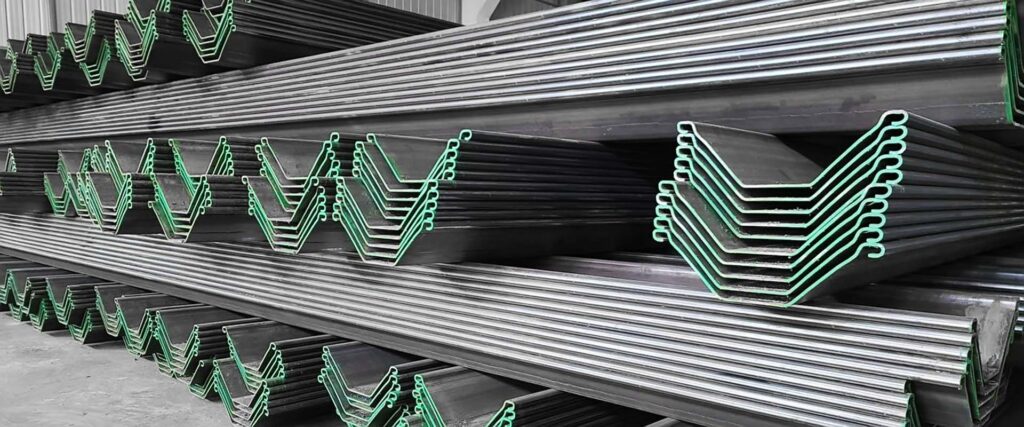

We focus exclusively on U-type, Z-type, and Omega-type steel profiles — selected for their strength, interlock integrity, and installation efficiency. These piles are available in a range of cross-sections and section moduli to accommodate both temporary and permanent applications. All products are manufactured to meet ASTM standards and are reviewed for compatibility with local and federal codes.

More than just a material supplier, we act as a sourcing partner. Our team coordinates global procurement, technical review, and delivery logistics to make sure your sheet piling system arrives on time, in spec, and ready for installation — no matter the site constraints or project phase.

Proven Use of Steel Sheet Piles in Modern Construction

Water Retaining Structures |

Basement Walls and Excavation Support |

| Steel sheet piles are extensively used to construct seawalls, quay walls, and cofferdams that retain or exclude water in marine and waterfront applications. Their interlocking profiles form continuous, watertight barriers capable of withstanding hydraulic pressure from tides, currents, and groundwater. | In urban environments, steel sheet piles are commonly deployed to stabilize excavations and prevent soil collapse during basement or utility construction. Their vertical alignment and minimal footprint make them ideal for zero-lot-line sites and congested project zones with limited workspace. |

Bridge Abutments and Riverbank Reinforcement |

Underground Parking and Deep Wall Systems |

| Steel sheet piling provides structural reinforcement along rivers, canals, and flood-prone areas. Used around bridge piers and abutments, sheet piles protect against erosion, scour, and washout, helping preserve infrastructure integrity in areas with high flow velocities or fluctuating water levels. | For below-grade parking structures and deep foundation walls, steel sheet piles offer a reliable solution for managing lateral soil pressure and water ingress. Their load-bearing capacity and tight interlocks make them well-suited for constructing durable, space-efficient enclosures in commercial and residential developments. |

Benefits of Steel Sheet Piles

High Load Capacity

Steel sheet piles provide excellent resistance to lateral earth and water pressure, making them ideal for deep excavations, quay walls, and flood defense. Their structural performance ensures safety and stability in both temporary and permanent works, especially where heavy surcharge loads or soil variability exist.

Modular and Space-Efficient

With their slim, interlocking profiles, sheet piles require minimal installation space, making them highly effective in urban construction and zero-lot-line projects. Their modular design allows for precise layout in tight or irregular geometries without compromising load-bearing performance.

Rapid and Low-Vibration Installation

Sheet piles can be installed quickly using pressing or vibratory techniques. In sensitive environments — such as near existing structures or in noise-restricted zones — low-vibration methods help reduce disruption and maintain structural safety during installation.

Corrosion Resistance for Harsh Environments

To ensure long-term durability, steel sheet piles can be supplied with corrosion-resistant coatings, galvanization, or paint systems. These treatments extend lifespan significantly, particularly in aggressive marine, coastal, or chemically exposed environments.

Reusability and Reduced Waste

Many sheet pile systems are suitable for extraction and reuse across multiple projects. This makes them a cost-effective solution for temporary works, while also reducing material waste and contributing to sustainable construction practices.

Watertight Interlock Design

The engineered interlock system creates a continuous, sealed wall that resists water seepage and soil migration. This feature is essential in cofferdams, basements, and riverbank applications where groundwater control is critical.

Fully Recyclable and Sustainable

Made from high-grade steel, sheet piles are 100% recyclable at end-of-life. Their extended service life, reusability, and minimal site footprint make them a preferred choice for projects targeting LEED certification and low environmental impact.

Compliance & Standards

All steel sheet piles sourced through A Priori Source are manufactured to meet or exceed the standards set by ASTM (American Society for Testing and Materials), including ASTM A572 and ASTM A328 for strength and durability. These specifications are essential to ensure structural integrity in retaining walls, deep foundations, and marine applications across varied soil conditions.

Our sheet piling profiles are also compatible with engineering design parameters set by U.S. agencies such as the Federal Highway Administration (FHWA), AASHTO (American Association of State Highway and Transportation Officials), and local Departments of Transportation. We ensure that supplied materials meet section modulus, yield strength, and interlock criteria typically required for public works and infrastructure projects.

Technical documentation, including mill certificates and compliance declarations, is available upon request to support your submittals and permitting process. Whether your project involves state highway embankments, urban excavation near utilities, or flood protection, our steel sheet piles arrive code-ready — backed by proven engineering and third-party validation.

FAQ

What are steel sheet piles used for in construction?

How are sheet piles installed — and does it cause vibration?

Are steel sheet piles reusable?

Do I need engineering approval or permits to use sheet piling?

How deep can steel sheet piles be driven?

Why Choose Our Steel Sheet Piles:

At A Priori Source, we do more than supply material — we deliver technically vetted, code-compliant solutions that fit your project’s structural and logistical needs. From profile selection to documentation, our team supports every stage of your sheet piling process with accuracy and accountability.

We work with a global network of manufacturers and provide only fully tested U, Z, and Omega-type steel sheet piles, configured to meet ASTM and project-specific design requirements. Each system is assessed for section modulus, interlock strength, coating compatibility, and installation constraints before shipment.

Whether you're building temporary excavation walls or long-term marine barriers, our sheet piling supply model ensures you get the right profile, the right support, and the right outcome — without delays or specification risks.

Verified compatibility with U.S. construction codes.

Every steel sheet pile we provide complies with ASTM standards (A572, A328) and aligns with AASHTO, FHWA, and DOT regulations. This means you can trust your selection meets federal and local code requirements for load‑bearing capacity, durability, and material quality.

Customized by application: marine, foundation, shoring, flood control.

We tailor each order based on actual project needs — whether it’s for coastal seawalls, deep foundation walls, or flood protection systems. That ensures you get an optimized solution for environmental conditions, installation depth, and performance expectations.

Single‑source coordination from procurement to delivery.

You benefit from streamlined communication and accountability — a single partner managing supplier vetting, quality control, logistics, and delivery schedules. This reduces administrative overhead and minimizes chances of specification errors.

Technical support, engineering data, and submittal‑ready documentation.

Beyond the product, we provide mill certificates, section modulus tables, interlock drawings, and installation guidelines. This allows you to streamline submittals, gain faster approvals, and ensure your team or contractor has built‑in reference materials.

Reliable lead times and logistics planning.

We track production schedules and coordinate shipments to align with your project timeline and site access constraints. You’ll receive timely updates and proactive management to keep your construction on track — not held up by materials.

Trusted Partner for Steel Sheet Pile Solutions

At A Priori Source, we understand the demands of real-world construction—tight schedules, complex site conditions, and performance expectations. That’s why our steel sheet piles are carefully selected for strength, interlock precision, and corrosion resilience, ensuring reliable installation for your excavation, foundation, or waterfront project.

We handle all the sourcing, quality control, and delivery logistics, giving you a seamless experience from procurement to installation. Our local support team coordinates with engineers and contractors to ensure your materials arrive ready to use—no delays, no surprises.

If you’re planning a project that requires deep walls, watertight enclosures, or vibration-sensitive installation techniques, contact us today. We’ll work with you to determine the right profiles, interlock types, and delivery timeframe—so you can focus on building, not sourcing.