- Home

- Products

- Construction Materials

- Aluminum Cladding Framing Systems & Aluminium Facades

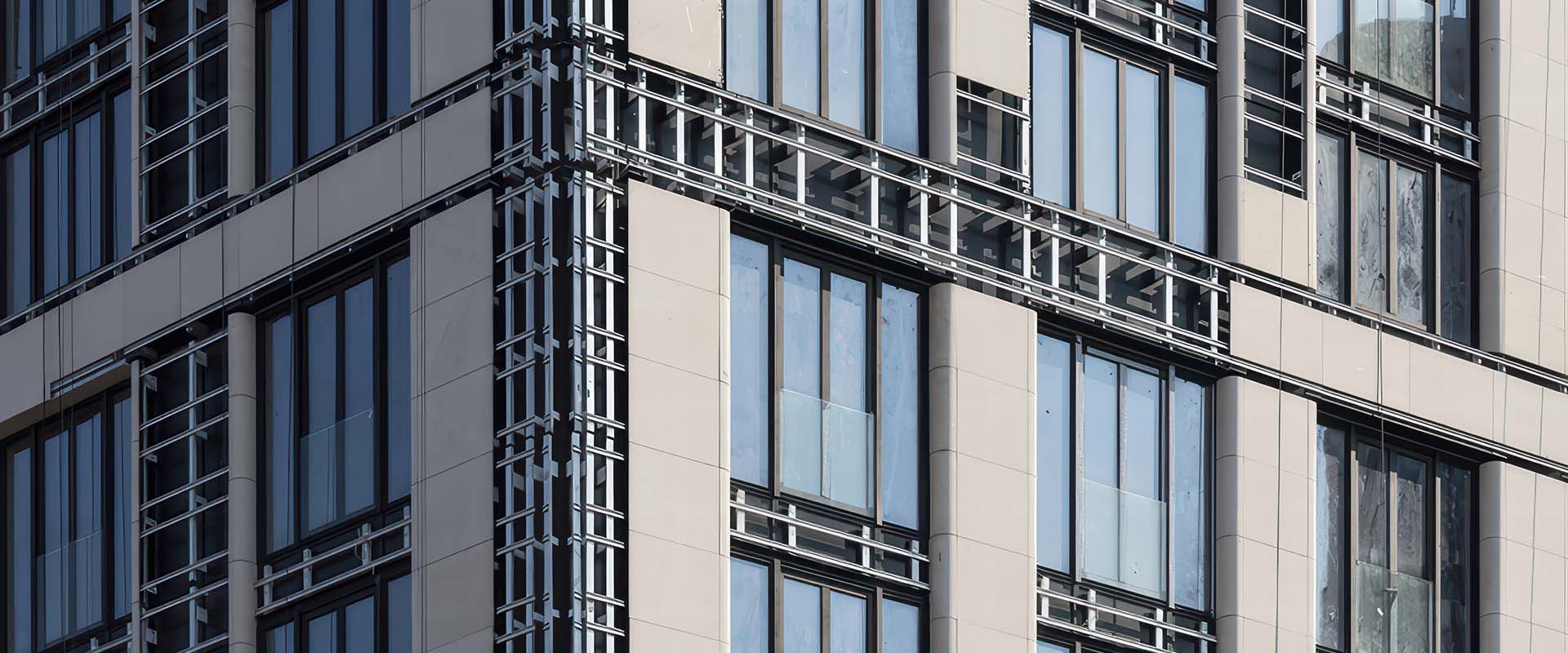

Precision-Built Aluminum Substructures for Modern Facade Cladding System

When the Substructure Fails: The Real Risks Behind Facade Cladding Systems

Behind every high-performance facade lies a precise structural backbone. When that aluminum substructure is misaligned, under-engineered, or installed without regard for building code requirements, the entire envelope is at risk. Failures in carrier profiles or brackets may go unseen during installation, yet over time they lead to panel deformation, thermal bridging, and compromised drainage performance.

These technical issues translate directly into cost and liability. Improperly designed aluminum support systems can cause delays, inspection failures, and warranty disputes. With stricter ICC and ASTM standards now governing rainscreen and ventilated facade systems, even minor deviations in subframe detailing can result in full-scale remediation or rejected approvals.

Ultimately, the real risk lies in treating the facade substructure as a commodity instead of an engineered system. When the supporting framework lacks precision, the building envelope loses its efficiency, safety, and long-term reliability—turning what should be a design asset into a maintenance liability.

Our Solution: Precision-Engineered Aluminum Cladding Subsystems for Modern Facades

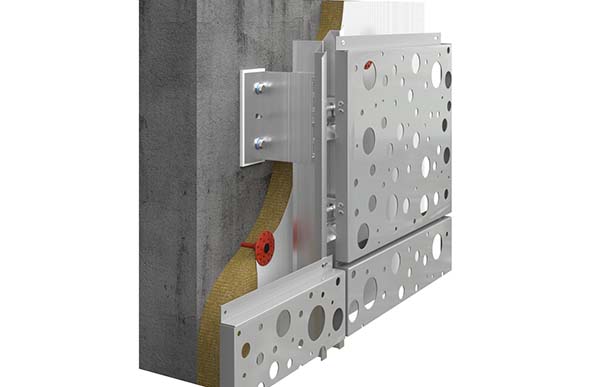

A Priori Source delivers aluminum cladding framing systems developed as fully engineered facade substructures, not isolated components. Each system combines precision brackets, carrier profiles, and anchoring elements into a coordinated framework designed to support modern facade cladding systems used in rainscreen and ventilated facade assemblies.

These aluminum substructure systems are engineered to resolve common performance challenges at the framing level. By maintaining consistent cavity depth, accurate panel alignment, and controlled load transfer, the framing system supports effective moisture drainage, continuous ventilation, and long-term dimensional stability. Integrated thermal break solutions further reduce thermal bridging and improve overall building envelope performance.

Our aluminum cladding systems are designed for broad material compatibility and regulatory clarity. The same framing principles apply to aluminum and aluminium facade substructures specified for projects operating under U.S. and international standards. Through precise engineering, documented system behavior, and coordination-ready detailing, A Priori Source enables facade cladding systems that perform predictably from design through installation and long-term use.

Aluminum Cladding System Types for Rainscreen and Ventilated Facades

Rainscreen Cladding Systems |

Ventilated Facade Substructures |

| Engineered aluminum framing systems designed for drained and back ventilated rainscreen applications. Each assembly includes precision brackets, carrier profiles, and adjustable rails that maintain cavity depth and alignment across the building envelope. The system supports multiple panel materials while ensuring moisture drainage, airflow, and long term facade stability under varying environmental loads. | These aluminum substructures enable consistent ventilation and thermal control behind the exterior cladding. Integrated thermal break brackets minimize heat transfer and prevent condensation, improving overall energy efficiency. Designed for compatibility with continuous insulation, ventilated facades deliver both performance and durability in demanding climate conditions. |

Thermally Broken Support Systems |

Universal Carrier and Bracket Assemblies |

| Thermally isolated aluminum support systems that combine structural strength with superior thermal resistance. Each bracket incorporates insulating pads or composite inserts to eliminate thermal bridging while maintaining load capacity. Ideal for high performance building envelopes where energy codes and sustainability targets require proven facade efficiency. | Standardized carrier and bracket assemblies designed to accommodate a wide range of facade cladding panels, including aluminum composite, fiber cement, terracotta, and stone. Modular profiles simplify layout adjustments and enable secure fastening while maintaining aesthetic continuity and structural precision across elevations. |

Adjustable Subframe Solutions |

Custom Engineered Facade Frameworks |

| Aluminum subframes with multi axis adjustability that allow precise alignment on uneven substrates. These systems include vertical and horizontal rails, adjustable facade brackets, and anchor sets optimized for wind load performance. Pre engineered slot tolerances reduce installation time while ensuring consistent spacing and code compliant anchorage. | For projects requiring unique facade geometries or hybrid material integration, A Priori Source provides fully engineered frameworks tailored to structural loads, thermal performance, and local code requirements. Each solution is documented with CAD and BIM details, ensuring clarity from design through installation and long term maintenance. |

ore Advantages of A Priori Source Aluminum Cladding Subsystems

High Structural Integrity

Aluminum cladding subsystems deliver exceptional strength-to-weight performance. Precision-engineered brackets and carrier profiles maintain consistent alignment under wind and live loads, ensuring long-term facade stability and reliable performance across all building types.

Thermal Efficiency and Moisture Control

Each rainscreen and ventilated facade assembly promotes proper drainage and continuous airflow behind the cladding. Integrated thermal break brackets minimize heat transfer and condensation, supporting continuous insulation and enhanced energy performance of the building envelope.

Corrosion and Weather Resistance

All aluminum components are fabricated from high-grade alloys with protective finishes that resist corrosion, oxidation, and environmental degradation. This durability ensures long-term facade performance with minimal maintenance, even in demanding coastal or industrial conditions.

Precision and Installation Flexibility

Adjustable subframe systems allow precise alignment on uneven substrates and complex geometries. Factory-engineered tolerances and standardized connections simplify installation while maintaining structural accuracy, reducing on-site adjustments and total installation time.

Code Compliance and Certification Support

A Priori Source systems are engineered to align with ICC, ASTM, and NFPA standards for aluminum cladding assemblies. Documentation packages include load tables, testing data, and specification support, helping ensure compliance from design submission to inspection.

Sustainable and Lightweight Design

The lightweight nature of aluminum reduces overall structural loads and transportation energy. Combined with full recyclability and compatibility with energy-efficient envelope systems, these subsystems contribute to sustainable construction and long-term environmental responsibility.

Compliance & Standards

Every aluminum cladding subsystem from A Priori Source is developed with code compliance as a foundational requirement, not an afterthought. Each component—brackets, carrier profiles, anchors, and thermal break elements—is engineered and documented to align with the most current provisions of ICC, ASTM, and NFPA standards governing exterior wall assemblies and aluminum structural components.

Our rainscreen and ventilated facade systems are designed for integration with continuous insulation and tested for drainage, fire resistance, and wind load performance. Detailed documentation supports code submittals, covering all relevant categories of the International Building Code (IBC), International Energy Conservation Code (IECC), and NFPA 285 compliance for fire-rated assemblies. These certifications ensure that every project meets both design intent and safety regulations.

By adhering to recognized material and installation standards, A Priori Source provides specifiers and contractors with reliable, inspection-ready facade substructures. Our approach ensures that aluminum cladding assemblies perform as engineered—maintaining envelope integrity, meeting energy targets, and securing long-term regulatory compliance across diverse building applications.

FAQ

What is the difference between a rainscreen system and a ventilated facade?

How do aluminum cladding subsystems improve thermal efficiency?

Are A Priori Source systems compatible with different cladding materials?

Do your systems comply with U.S. building and fire codes?

What maintenance do aluminum facade substructures require?

Why Construction Teams Choose A Priori Source for Cold-Formed Steel Framing Solutions

A Priori Source is more than a materials supplier — we are a technical partner focused on accuracy, compliance, and project performance. Our team supports every stage of facade system development, from early design coordination and substructure selection to code documentation and installation guidance. This integrated approach ensures that each aluminum cladding subsystem performs exactly as engineered, with no compromise in safety or efficiency.

We maintain direct collaboration with architects, structural engineers, and contractors to simplify design decisions and eliminate compatibility risks. Through detailed CAD and BIM resources, load tables, and specification documents, A Priori Source provides the data and clarity needed for precise project execution. Our engineered frameworks are backed by technical validation and full traceability of materials and performance results.

Choosing A Priori Source means choosing reliability in both engineering and delivery. We manage the entire supply chain of aluminum facade subsystems — from design support to packaging and logistics — ensuring consistent quality, predictable lead times, and verified code compliance. Our mission is to help clients achieve long-term envelope performance and peace of mind in every project.

Engineering-Based Product Selection

Every aluminum cladding subsystem offered by A Priori Source is selected and specified through an engineering-first process. We evaluate structural loading, thermal requirements, and local code conditions to recommend the most appropriate substructure and fastening configuration for each project.

Comprehensive Design Documentation

Our team delivers detailed CAD and BIM files, load tables, and testing data for all aluminum cladding systems. This documentation supports permit submittals, simplifies coordination with other trades, and ensures that every component of the facade assembly is verifiable and inspection-ready.

Integrated Code and Compliance Support

A Priori Source provides full technical assistance in meeting ICC, ASTM, and NFPA standards for exterior wall assemblies. We help clients navigate code requirements, evaluate fire rating compatibility, and prepare submittal documentation that satisfies both design intent and jurisdictional review.

Reliable Supply Chain and Quality Control

All aluminum substructure components are sourced through verified manufacturing partners and undergo quality control aligned with international standards. We manage logistics and traceability from factory to site, ensuring predictable lead times and consistent product performance.

Dedicated Technical Partnership

We operate as part of the project team, not just as a supplier. A Priori Source supports architects and contractors through every stage — from conceptual design to installation oversight — helping prevent specification errors, delays, and cost overruns while ensuring that the final facade system performs as engineered.

Building Trust in Aluminum Cladding Systems Through Precision and Proven Facade Performance

Every engineered building envelope depends on the reliability of its substructure. A Priori Source delivers precision-built aluminum cladding subsystems designed for consistent alignment, thermal stability, and long-term compliance with ICC and ASTM standards. Each rainscreen and ventilated facade solution we provide is backed by full documentation, performance testing, and verified material traceability.

Our commitment extends beyond supply — we partner with design teams and contractors to ensure that every aluminum support system functions as intended. From specification to installation, A Priori Source brings the accuracy, transparency, and technical expertise needed to build facades that meet the highest standards of efficiency and code compliance.

Contact A Priori Source to request engineered specifications or discuss how our aluminum cladding systems can support your next facade project.